OUR MISSION

ALWAYS INVESTING IN BETTER, SAFER WORK

We’re committed to investing in new technology, smarter processes, and more efficient systems. From upgraded tools to enhanced inspections, we continuously improve to stay ahead and maintain high standards while working faster and safer.

At Airco Inc, our pledge is to lead the industry in cutting-edge surface preparation, painting, coatings, and linings systems that not only protect but also enhance coating performance. Our focus revolves around upholding top-tier safety and quality standards, as well as implementing environmentally friendly practices while fostering relationships with our business partners, employees, and community leaders.

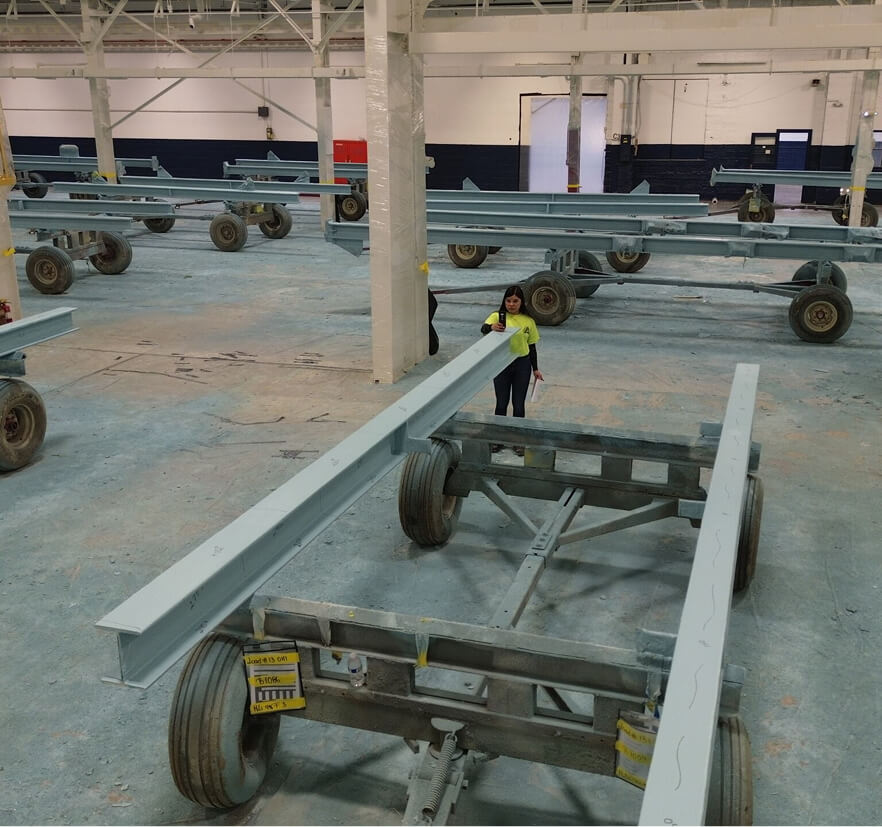

HIGH-VOLUME SHOP CAPABILITIES

At Airco, our shop facilities are engineered for serious throughput. With temperature-controlled workspace and a proprietary steel movement process, we’re built to handle the largest and most time-sensitive industrial coating projects in the country.

Our system is designed for flow — not friction. By strategically staging material and optimizing every transition from blasting to coating to curing, we eliminate bottlenecks and accelerate production timelines. This efficiency is powered by the ability to run up to 18 blasters & 12 applicators simultaneously, allowing us to move high volumes of steel through the process without sacrificing quality or control.

BUILT ON SAFETY.

BACKED BY QUALITY

Our dedication to safety and quality is about delivering peace of mind. Whether we’re working on a small project or a massive undertaking, you can trust that we’ll treat it with the care and attention it deserves.

LEADING WITH STANDARDS

STEVEN HINSON, NACE LEVEL 3

To maintain our quality standards, we’re always investing in the latest equipment and technology. Whether it’s upgrading tools or streamlining processes, these investments help us work smarter, safer, and more efficiently. Steven is constantly on the lookout for innovations that enhance safety and quality. His attention to detail ensures that we’re setting the industry standards.

RED-TAGGING

Our red-tagging system makes safety a daily habit. Each time a tool or piece of equipment returns from use, it is inspected, maintained, and tagged out of service until it is verified safe to use again. This ensures that every item heading to a job site is in peak condition and ready to perform safely.

WEEKLY SAFETY AUDITS:

STAYING AHEAD OF RISK

We conduct detailed safety audits every week — in the field and across our shops. These inspections cover everything from equipment condition to jobsite practices. Our QA team uses a proactive approach to identify potential risks and correct them before they become problems. This keeps our people safe and our projects running smoothly.

QUALITY ASSURANCE

YOU CAN COUNT ON

With up to 20 QC inspectors on-site at any given time, our quality control process is as thorough as it is efficient. Our QA team checks every step of every project — from surface prep and coating application to environmental conditions and reporting. That’s how we ensure our finishes last and perform under pressure.

LET US PROTECT YOUR NEXT PROJECT

Whether you’re lining up a multi-phase development or need a partner to keep your project on schedule and spec, Airco brings the people, equipment, and experience to deliver.